With the rapid development of the photovoltaic industry, recycling photovoltaic panels has become a crucial task. Recovering valuable materials from used photovoltaic panels is crucial. Precious metals such as silicon and silver can be extracted from the solar cells within used photovoltaic panels, while other materials such as glass, backsheets, and metal frames can also be effectively recycled. Through this physical separation method, the economic value of the materials contained in 800,000 tons of used photovoltaic waste is estimated at $1.25 billion. Increasing resource reuse can reduce the exploitation of natural resources, reduce environmental pollution, and achieve sustainable development.

The physical separation process for used photovoltaic panels primarily involves four steps: 1. Frame removal, 2. Junction box removal, 3. Glass removal, and 4. Glass sorting. The main process of crushing and sorting: scrapped photovoltaic panels are shredded in a shredder. The shredded materials are then crushed in a dedicated crusher to separate the EVA film and monocrystalline silicon wafers. The dispersed materials are then fed into a collector via an induced draft fan. After sorting, the silicon is separated. The remaining mixed materials then enter a dedicated crusher and, after passing through an air lock, enter an airflow sorting screen. The airflow and vibration remove positive metals and plastics, while also collecting the dust generated by the airflow sorting screen.

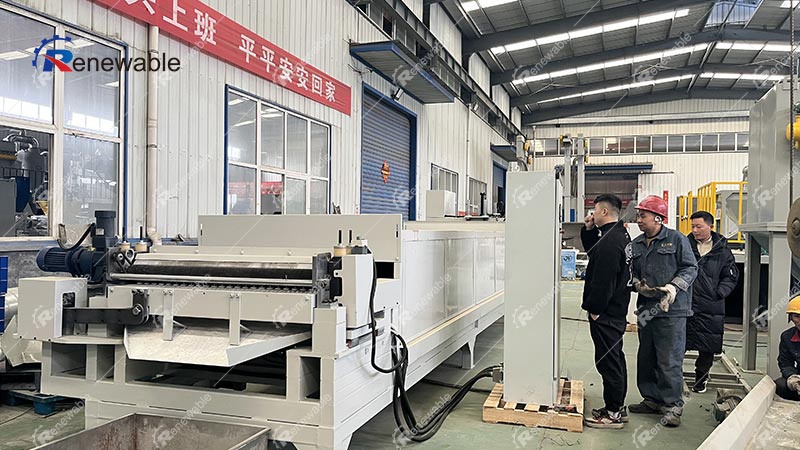

Henan Renewable Energy Technology Co., Ltd. is committed to reducing negative environmental impacts. Through efficient processing technology and equipment, harmful substances in scrap photovoltaic panels are safely treated to prevent soil and water pollution. Resource reuse also reduces damage to the natural environment, reduces energy dependence, and contributes significantly to green development, resource recycling, and environmental protection.